installation of heat pump ventilation and heat recovery ventilation

One

of the main components of the ventilation system, is the ductwork that

transports the air. The system is individually designed to the

structural conditions and layout of the property.

We recommend rigid metal safe-seal duct for maximum efficiency, health

benefits and durability. To ensure maximum heat recovery and virtually

silent operation, high quality thermal insulation and acoustic duct is

used. In limited spaces such as ceiling voids or barn conversions, where

there is exposed roof structure, special low-profile flat metal duct can be

specified. The ductwork can usually be hidden quite easily around the

house. For heat recovery ventilation systems installed in a renovation, it is sometimes prudent to use radial plastic duct with a 90mm diameter. However, two or more ducts may need to be installed per room to obtain the necessary airflow. There are several types of duct available and we have highlighted their advantages and disadvantages in this document, so that you can easily undertand the advantages of rigid metal safe-seal ducting.

For an installation manual, please visit our downloads section.

The Loft

This

is normally an area where you can run the ductwork freely from the ventilation appliance to the ceiling terminals in the ceiling of the floor

below (usually the first floor). The duct is usually at a 200mm/250mm

diameter at this stage coming straight off the appliance and it will

reduce down to 100mm/125mm to be connected to the ceiling terminals.

If

you are using the loft as habitable space as well, hopefully there will

be some dead space created on either side, by the pitch of the roof.

Check the specification of the ventilation appliance that you think is

suitable for your property, to work out the minimum space required. For

access to clean the filters, it will be best to leave approximately

600mm in front of the appliance, or integrate an access door within the

wall so that the appliance remains accessible.

The best location is to have a dedicated PLANT ROOM, but alternative

locations for the appliance can be in large cupboards, loft or perhaps in

your utility room.

Although

a ventilation appliance from Total Home Environment runs pretty much silently, if it has to be located in a loft, you will usually

locate it above a bathroom or dressing room, to minimise the risk of

noise caused by vibration. The ventilation appliance should be mounted on

plenty of insulation on top of the joists, or on the wall. The

appliances weigh between 40-225kg, but it is best to check the

specification sheet for the exact weight of the appliance, to ensure the

surface it is to be mounted on, will have a satisfactory weight-bearing

capacity.

The

appliance will produce approximately 3-5 litres of moisture in the

winter months, so you will need to fit a condensate pipe to a trap

linked to your internal waste water pipe.

You

need to be aware of where you can locate the two louvres, for the

fresh-air intake and stale-air outtake. These need to be placed a

MINIMUM of 3m apart horizontally or 1m apart vertically to stop

cross-contamination. They can be located on the gable end of the loft

area, under the eaves or you can have special roof vents which your

roofing contractor can supply you with.

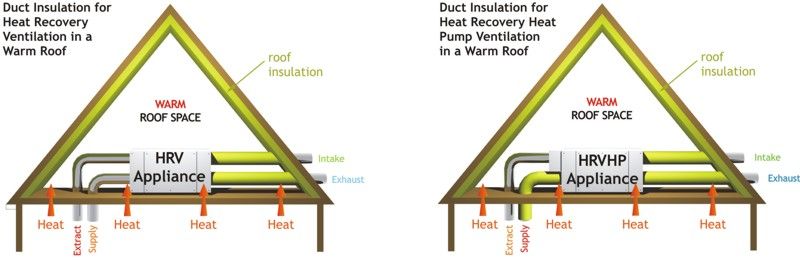

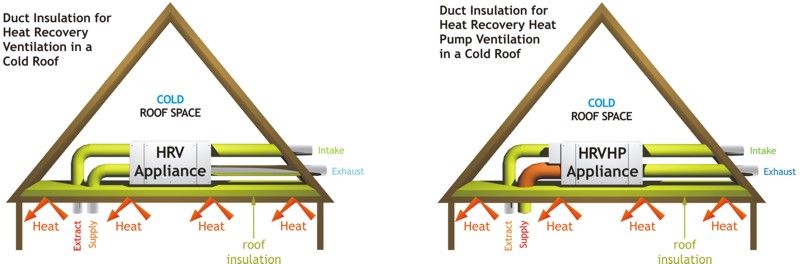

Will the property have a warm roof or a cold roof? This is very important to establish with your architect or builder

before we complete a quote for you, as it will effect the insulation

properties of the ductwork that may run in this area.

A warm roof is where the insulation is placed in the roof

itself, therefore making the roof area warm. If insulation is only going

to be placed in the floor of the loft area, this is known as a cold

roof as the loft area will be cold in comparison to the rest of the

house.

If you have a cold roof construction the extracted air ducts

from kitchens and bathrooms and the supply air ducts to the habitable

rooms of the house will need to be well insulated where they are in the

loft area. This will obviously increase the cost of the quotation so

that more insulation can be accounted for.

Duct Route

Rigid metal ventilation ductwork

In

the ceiling voids, you will mainly have to run the ductwork with the

joists, unless of course your floor construction allows for ductwork to

go through it, ie posi joists or i-beams. Always check with your builder or

surveyor where holes can be made and how big they can be through any joist structure.

PVC flat channel ventilation ductwork

To drop down to the lower floors you can utilise the following spaces:

- soil-pipe boxing or existing boxing-in

- airing cupboard

- boiler cupboard

- fitted wardrobe

- coats cupboard

Ceiling Terminals

The ideal place for locating ceiling terminals is opposite a

door but next to a window, so you create air circulation. Of course when

you get downstairs or to the lower floors, you are more restricted on

where you can put the terminals, as you will be channelled by your

route.

Most

of the time, the terminals downstairs are likely to be at the corners

of the room where the voids to drop the ductwork down, are likely to be

above.

Occasionally

you can use low profile duct to drop down a timber partition, but for

airflow purposes, it is best to restrict the use of this flat channel

ducting as much as possible.

Wiring-Up

The

ventialtion appliance itself would normally need to be wired into your house

electrics by a qualified electrician, although if you have an

electrical socket nearby you may be able to just plug in there. It will

be best to speak to your electrician first.

The

controller should be placed in a hallway or landing where you will have

convenient access to alter the program or put the system on boost. Low

voltage cable needs to run from the controller to the ventilation appliance and any PTC heated ceiling terminals you may have (HPV Series) system only).